Rapid prototyping systems (or rapid prototyping) are able to build the prototype of a detail starting from the corresponding CAD model, without any limitation deriving from geometric complications (first of all undercuts and internal cavities); the prototyping process is carried out by exploiting multiple additive construction technologies by layers, subject to continuous evolution.

Upward leverages the following technologies:

polyjet

Selective Laser Sintering (SLS)

Fused deposition modeling (FDM)

Lost wax investment casting

The operating principle used for the realization of the prototype is the jet printing of a photopolymer: a multi-nozzle head deposits successive layers of photopolymer which are solidified one after the other using UV lamps. At the end of the construction phase the i supports and it is possible to proceed with the possible manual finishing of the piece.

The SLS technology exploits the energy (heat) produced by a special head which, by directing the laser beam onto the powdered material, causes its dissolution and therefore solidification. It is possible to obtain products with high mechanical characteristics, using the filler in nylon, nylon filled with fiber glass or carbon. For special needs, the prototype can be obtained by laser solidification of steel powder.

The FDM technology provides for the construction of the object through the deposition in the molten state, by means of a heated head, of layers of plastic material wire (ABS) which then solidifies in a controlled temperature environment. The dimensional stability of the produced object is ensured by the deposition simultaneously with ad hoc support which is removed at the end of the process. FDM technology stands out for its relative simplicity and the possibility to choose between multiple colors.

Lost wax investment casting allows you to obtain metal objects starting from a wax model obtained from rapid prototyping: the latter is covered with a refractory shell that resists the casting of the molten metal which melts the lost wax. The investment casting can subsequently be worked on machine tools to obtain a functional prototype.

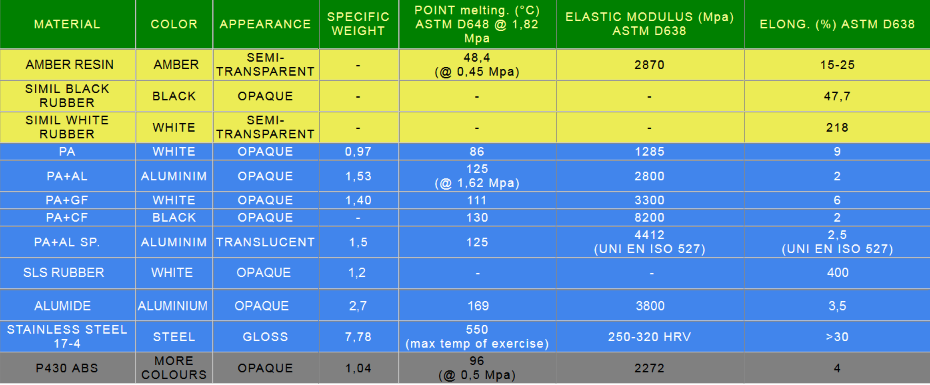

N.B: THE DATA REPORTED REFER TO SAMPLE TESTS

PROTOTYPES MADE FROM BILLET

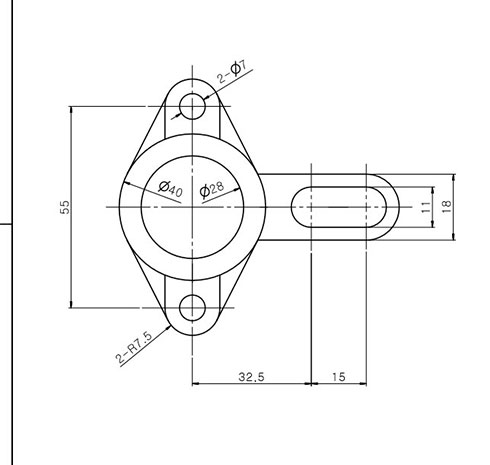

We are able, using our dedicated machining center, to create prototypes machined from solid (bars, plates, etc.). In order to create the required details, the files are acquired directly in DXF, DWG, ESP, IGES, VDA, STL, CATIA, Parasolid, SolidWorks, etc. formats. and subsequently adapted. With the appropriate translators, the drawing created on the computer is transferred to the machine tool for the creation of the machined component.

Our story begins with a dream in the drawer,

the dream of having the possibility to revolutionize the world